At WCR, we understand what it takes to help ethanol production facilities of all sizes reach peak performance.

As the leader in heat exchanger parts and service, here’s how we support our valued customers within the ethanol industry:

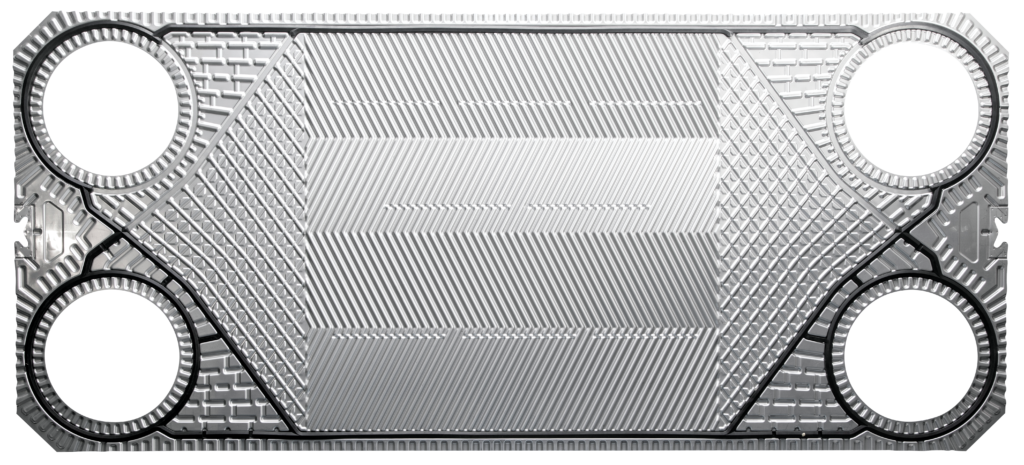

When a heat exchanger is down in your ethanol plant, your productivity is down, too. You can’t afford to wait weeks or even months for replacement heat exchanger components to be shipped overseas — you need the right parts, right now. Turn to WCR for OEM-quality heat exchanger spare parts specified for ethanol production!

As the largest domestic producer of heat exchanger plates and gaskets, WCR maintains an inventory of over 200,000 heat exchanger plates and over 600,000 gaskets, in stock and ready to ship anytime. We have in-stock components and support for the following key heat exchanger models for the ethanol industry:

Because WCR manufactures heat exchanger plates and gaskets right here in the USA, we can ship spare parts to your ethanol plant at a moment’s notice.

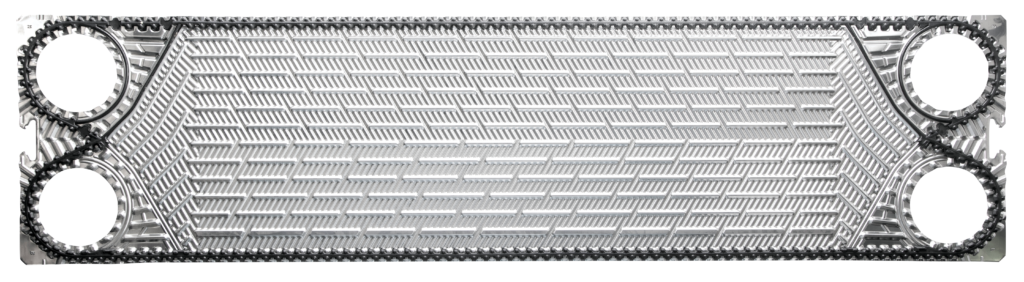

Ethanol plants must schedule regular service intervals to address fouling and other common heat exchanger maintenance issues. To reduce downtime and maintain the pace of production, these heat exchanger Clean in Place (CIP) services need to be completed within a tight timeframe, usually within 24 hours.

When time is of the essence, you can count on the trained service professionals at WCR to provide quality preventative maintenance and heat exchanger cleaning services.

Our trained service professionals know ethanol heat exchangers inside and out. During our signature Open, Wash, and Close service, they’ll start by opening the heat exchanger unit and washing all plates to remove loose scaling or fouling. Then, they will inspect and repair or replace gaskets as needed. Finally, they will close the units and ensure you get operations back up and running smoothly.

Best of all, WCR’s strategic locations enable us to provide expedited service and support for the rapidly growing ethanol market, with centralized facilities based in California, Illinois, and Ohio, and additional operations to come in the future.

In addition to planned seasonal service shutdowns, most ethanol plants experience urgent maintenance needs throughout the year. That’s why WCR’s trained field service technicians are always on call and available for on-site emergency maintenance and repairs.

With A+ ratings from Avetta, ISnet, Appruv, First Verify, and other leading safety organizations, WCR’s expert service teams have years of cross-brand knowledge and experience handling all models of plate heat exchangers. You can trust they have the know-how to tackle any heat exchanger maintenance or repair problem in your ethanol plant.

At WCR, we’re committed to supporting the future of the biofuel industry. That’s why we offer skilled engineering support for new custom heat exchanger equipment design, existing equipment resizing, and direct drop-in replacements for major heat exchanger lines as your company grows and diversifies.

WCR also offers spare parts inventory management to free up more space and resources in your facility. For the ultimate convenience, we’ll even handle the pickup and delivery of spare parts when you need them.

WCR is your go-to for OEM-quality replacement parts, expert service and support, and heat exchanger manufacturing expertise for ethanol production. For more information about our heat exchanger service and support capabilities in the ethanol industry, download our free brochure.

Are you planning an upcoming heat exchanger service interval at your ethanol plant? We want to help you maximize your facility’s downtime and protect the longevity of your heat exchanger equipment with quality preventative maintenance services. Contact the heat exchanger experts at WCR to learn more and get started today!