From plastics to perfume, clothing to cleaning products, fertilizer to fuel and so much more — chemicals play a role in nearly every aspect of our daily lives. As an integral component of our nation’s economy, the U.S. Chemical Sector converts raw materials into more than 70,000 diverse products distributed to over 750,000 end users. In 2016 alone, 96% of U.S. goods were manufactured using chemical products!

Chemical production involves a precise and complex combination of heating, cooling, and interchanger processes, making heat exchangers essential equipment across a wide variety of applications. As a reliable partner for chemical producers, including some of the top Petroleum, Hydrocarbon Processing and Polymer Plants nationwide, WCR has the heat exchanger parts, service, and support you can count on.

Take a look at how WCR helps companies in the chemical industry achieve high performance with heat exchanger solutions:

Because today’s chemical plants operate with high-dollar value media — such as the amines used in many petroleum refineries — minimizing product loss is a top concern. WCR offers new heat exchanger units with low hold-up volume, enabling chemical processors to recover as much product as possible.

Our new heat exchangers are available in multiple plate angle configurations, ideal for evaporating, condensing and batching applications. Whether you’re looking for WCR’s new heat exchangers in 1” to 12” connections or custom drop-in replacement heat exchangers for all major name brands (even obsolete lines), we have what you need. In fact, our new chemical heat exchanger units can be produced and shipped in less than twelve weeks to assure minimal downtime and keep your plant flowing smoothly.

Creating — and controlling — chemical reactions requires the right equipment, especially when handling corrosive media such as hydrogen sulfide, hydrochloric and hydrofluoric acids and the possible byproducts that can be formed. WCR specializes in manufacturing durable, chemically-resistant heat exchanger replacement parts to provide optimum compatibility, performance and safety within your chemical processing plant.

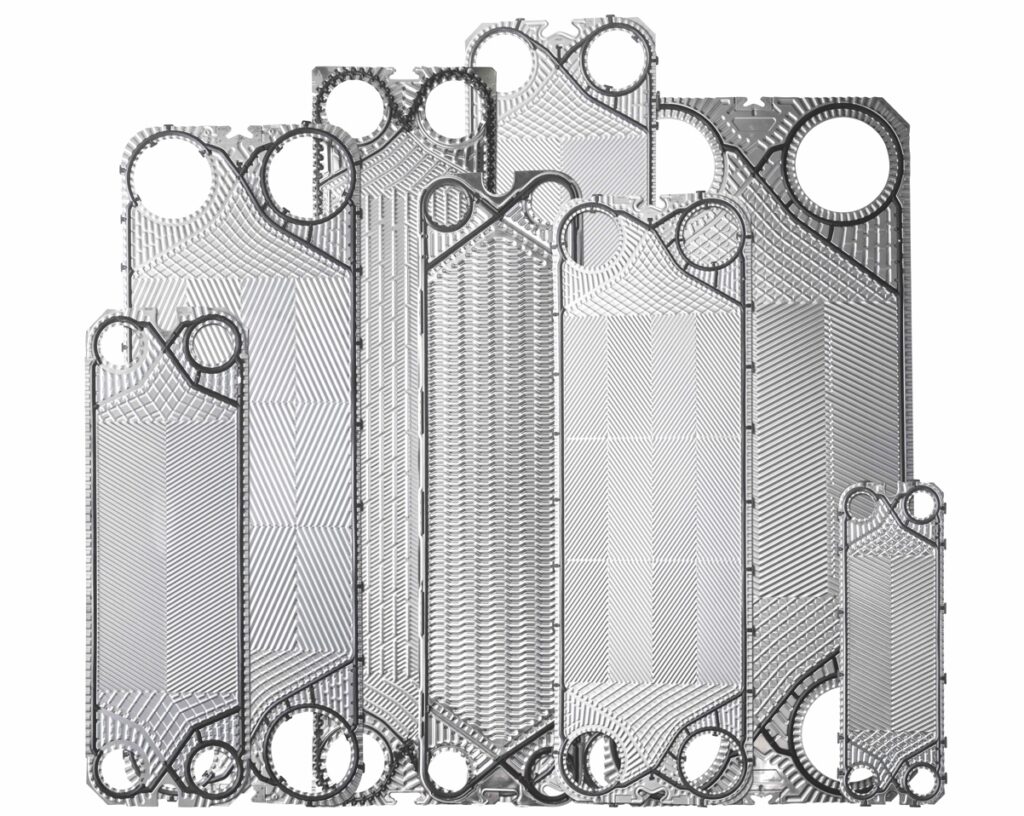

WCR’s heat exchanger plates are custom designed to be direct replacements for all OEM model plate heat exchangers, with high-alloy and chemically-resistant materials available. We know that polymers and additives affect which chemicals a rubber material can withstand, which is why WCR compounds rubber materials for superior performance.

Our OEM-specified replacement heat exchanger gaskets are also designed to provide the durability today’s chemical processors depend on. We work closely with the world’s leading suppliers of raw rubber materials to assure the highest quality from the very start, offering upgraded heat exchanger gaskets made from innovative materials such as High Temp EPDM, High Temp HNBR, NEOPRENE®, AFLAS®, Viton™ and Teflon®.

WCR’s heat exchanger replacement parts are manufactured domestically, and we have over 200,000 plates and over 600,000 gaskets in stock — usually available to ship within 1-2 days. With expedited turnaround, rigorous standards for quality and safety and the largest heat exchanger spare parts inventory in North America, WCR is your go-to supplier for quick and convenient heat exchanger replacement components.

In addition to new chemical heat exchanger units and direct heat exchanger replacement plates and gaskets, WCR also offers the heat exchanger service and support your chemical processing plant needs to perform at its peak. For chemical companies, running reactive heat exchanger maintenance poses significant risks in terms of cost, inventory management, and safety. That’s why we work side-by-side with our chemical customers to plan ahead and maximize downtime with strategic, cycle-based preventative maintenance programs for heat exchangers.

WCR offers a network of 21 expertly-trained field service teams across the United States, with the ability to reach any destination within 8 hours for both planned maintenance and emergency service. Our heat exchanger service professionals conduct comprehensive on-site audits, including hazardous process monitoring, to meet all your chemical heat exchanger maintenance needs with an uncompromising commitment to quality and safety.

WCR provides top-tier heat exchangers and heat exchanger replacement parts for companies that specialize in refining crude oil and chemicals, helping our partners in the chemical industry improve productivity and performance while minimizing product loss and costly unplanned downtime.

To learn more about WCR’s heat exchanger solutions for a wide array of chemical applications, download our free brochure. When you’re ready to build your spare parts inventory, schedule heat exchanger maintenance or order a custom-built heat exchanger unit for your chemical plant, we’re always here to help you. Get in touch with our heat exchanger experts today.